Nylon 66 is a high-performance polymer with the chemical name polyhexamethylene adipamide (PA66) that has the characteristics of high strength, high temperature resistance, and wear resistance.

Nylon 66 is synthesized by polycondensation of hexamethylenediamine and adipic acid. Equivalent amounts of hexamethylenediamine and adipic acid are mixed with water in a reactor to form nylon salt, which is then polymerized in a continuous or batch manner to form nylon 66. This material can be spun into fibers by extrusion granulation or by extrusion cooling through a spinneret to form filaments.

Main characteristics:

High strength and rigidity: Able to withstand large mechanical loads.

Heat resistance: High melting point, able to maintain its mechanical properties and chemical stability at higher temperatures.

Wear resistance: Able to resist wear and friction, suitable for high wear environments.

Oil resistance: Good corrosion resistance to a variety of oils and solvents.

Self-lubricating property: Low friction coefficient, able to operate without lubrication, reducing friction and wear.

Chemical stability: Able to resist corrosion by chemicals such as acids and alkalis.

Stress cracking resistance: Not easy to crack when subjected to stress.

Hygroscopicity: Able to maintain its mechanical properties in a humid environment.

Application:

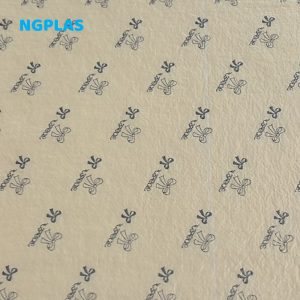

Textile industry: Used in the production of textiles, carpets and molded parts.

Automobile manufacturing: Used for parts under the hood, such as radiator end covers, intake manifolds and oil pans.

Electronic and electrical: Used for electrical insulation components, pipes, machine parts, etc.

Other applications: Zipper tapes, conveyor belts, hoses, guitar nut materials, etc.

| Item | Testing Standard | Testing Condition | Unit | G6030 | I1046 | F8130 |

| Tensile Stress | GB 1040 | 50mm/min | MPa | 159 | 130 | 98 |

| Tensile Strain | GB 1040 | 50mm/min | % | 6.8 | 5.1 | 5.1 |

| Flexural Strength | GB 9341 | 2mm/min | MPa | 220 | 215 | 160 |

| Flexural Modulus | GB 9341 | 2mm/min | MPa | 6862 | 7668 | 6822 |

| Impact Strength | GB 1043 | 2mm Gap | KJ/m² | 14.5 | 9.8 | 7.3 |

| Density | GB 1033 | 23℃ | g/cm³ | 1.39 | 1.46 | 1.46 |

| Melt Flow Index | GB 3682 | 230℃/2.16KGS | g/10min | 40 | 52 | 65 |

| HDT | GB 1634 | 0.45MPa | ℃ | 225 | 235 | 220 |

| Flammability | UL94 | 3.2mm | / | / | V0 | V0 |